- Home

- Product

- Heavy Hydraulic Cylinder

- Tie Rod Cylinder

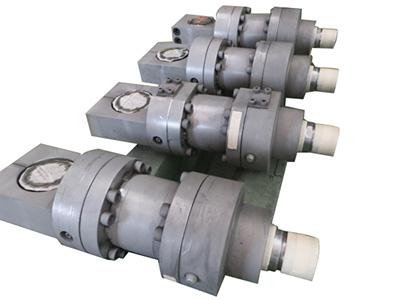

Tie Rod Cylinder

The cross tie-rod hydraulic cylinder is one of the most common hydraulic cylinders, usually utilized in engineering equipment. Compared to other industry cylinders, the cross tie-rod hydraulic cylinder features lighter weight, easier installation, simpler maintenance and various installation methods. The cross tie-rod cylinders we produce are certified by ISO9001 quality management system. Three kinds of pressure cylinders are provided: 7MPa, 14MPa and 21MPa and custom hydraulic cylinders are also available based on your exact needs. All of our seals utilize components from PARKER or MERKER and floating bushings and Floating cushion sleeves are mounted on both ends, which assures the concentricity of the annular flow gap, improves cushion performance, lowers internal and external impact and noise and extends the working life of hydraulic cylinder.

The high pressure resistant inductive switches are installed at the limit position of both two ends of the tie-rod cylinders, which eliminates the cumbersome steps of designing and installing the limit switches on the moving mechanism, and provides great convenience for design and installation adjustment. The drawbar cylinder can be equipped with a built-in displacement sensor, which can accurately stop according to the needs of industrial and mining. Under the coordination of electronic control and hydraulic control system, high-speed and precise industrial automatic control can be realized.

The cross tie-rod cylinder displacement sensor works under the principle of magnetostriction. When the moving magnet magnetic field intersects with the magnetic field generated by the waveguide current pulse in the sensor, continuous strain pulses are generated to sense the piston’s movement position (or movement speed). Since the sensor elements are non-contacting, the continuous sensing process will not cause any wear on the sensor, and can withstand high temperature, high pressure and high impact working environment. These hydraulic cylinders are mainly used in machine tools, woodworking machinery, rubber machinery, steel equipment, injection molding machines, die casting machines, offshore or onboard installations. Here are the cross tie-rod cylinders we have manufactured.

Pressures: 20000PSI

Bores sizes: 1-1/2" through 78"

Stroke Length:up to 980"

Standard fluid: Hydraulic oil

Standard temperatures: -10°F to +165°F

Piston rod diameters: 3/4" through 50"

Acting:Double or single acting

Material:High yield carbon or alloy steel outer tubes and stages